BrewMonitor: A Look at Fermentation Data Curves – Yeast Issues

BrewMonitor® offers your brewing team access to insight that has never been available before: high-resolution data from inside your fermentation tank, allowing you to track the progress of your fermentation, analyze results, benchmark future batches, and much more. The resulting graphs for each completed fermentation – dissolved oxygen, pH, gravity, pressure, temperature and conductivity – provide extremely clear views into the events that transpired and techniques that were employed. This series of articles shows examples of data curves from specific parameters, as they were recorded from the fermentation of various styles in different scenarios. These graphs are from actual fermentations, and offered as a look into how these conditions express themselves as measured data trends.

In this installment, we show examples of how yeast issues are expressed.

See our earlier post on typical gravity curves »

See our earlier post on typical pH curves »

See our earlier post on typical conductivity curves »

See our earlier post on fermenter failures »

Unhealthy Yeast

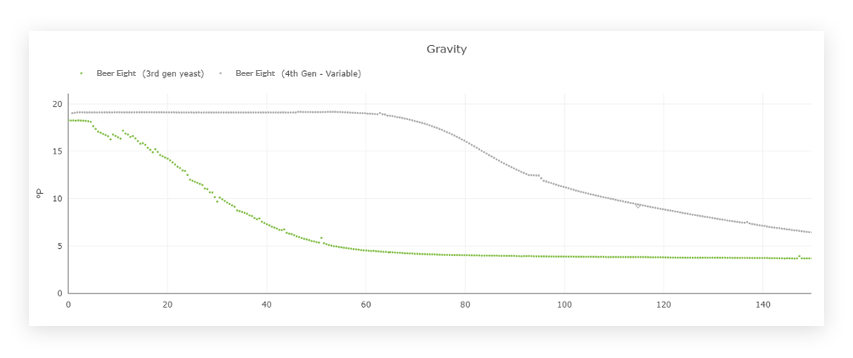

The graphs above (Figure 1) show two fermentation batches of the same beer. Both show gravity readings taken every 30 minutes for 150 hours from the time of the initial pitch of yeast. In green, the healthy fermentation begins within about five hours of the pitch. For the subsequent batch in gray, no discernable fermentation activity begins until around 60 hours after the initial pitch. In this second case, the BrewMonitor System was used to confirm the lack of activity and the relative lack of health of the yeast. The batch was recovered by injecting a fresh pitch of yeast at 50 hours.

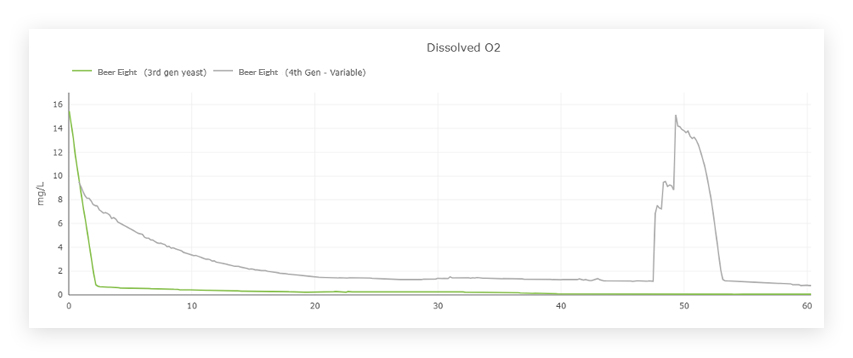

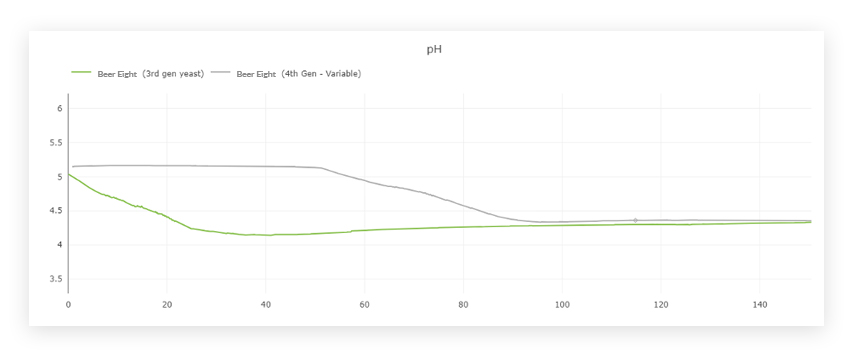

Also notable are the relative readings on dissolved oxygen (Figure 2) and pH (Figure 3), shown below. In both cases, the stalled fermentation shows slow or no rates of change relative to the healthy fermentation. With oxygen readings, it’s clear that the brewer aerated the wort as they injected fresh yeast at around hour 50 for the data in gray. On the pH graph, notice the distinct lack of movement until after hour 50 when the fresh yeast is added.

A pitch of healthy and vital yeast would begin to change their environment as soon as they hit fresh wort. This can be seen clearly in the “3rd Generation” pitch, where the yeast acidify the wort and consume oxygen within minutes of pitch time (note: X-axis origin is time of pitch as reported by the brewer). One can therefore conclude that the yeast crop underwent too much stress between its 3rd and 4th pitch to maintain enough vitality to ferment another high gravity beer.

Underpitching

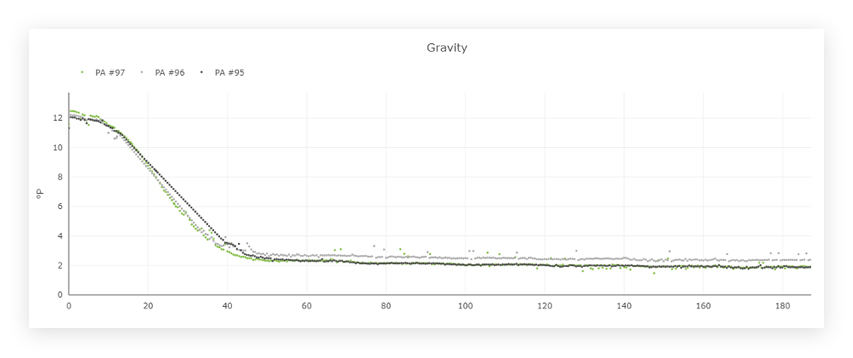

Sensory issues can also arise during fermentation in ways that are detectable when monitoring with high frequency data streams. For example, the graph below (Figure 4) shows three sequential batches of the same beer, brewed in series by a brewery that used the BrewMonitor System to track their progress.

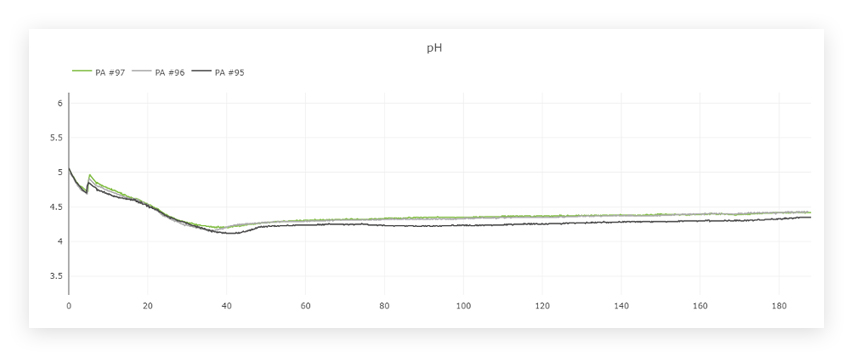

Notice how the gravity readings align, with batch #96 only about a 10th of a degree plato above the other two fermentations. In fact, it was batch #95 that expressed a notable sensory issue with an ester profile that pushed into a notable “nail-polish remover” quality. While these gravity graphs are so closely aligned that they don’t betray enough variation from #95 to the other two, the pH readings (Figure 5) show a marked difference:

Here, the pH for #95 drops below the other two batches sometime shortly after hour 30. It remains lower for the duration of fermentation, never recovering back to the same relative measures of the other two batches. This indicates an increase in the acidification of the wort caused by the yeast.

After each of these batches were finished, the brewery conducted a sensory evaluation. Once the significant variation in the ester profile for batch #95 was noted, the brewery was able to use the pH and gravity data seen here to confirm that the yeast had behaved errantly. By comparing this data with their cell viability data, they were able to pinpoint the cause of the issue to a slight underpitch (one that would have otherwise been considered within an acceptable margin of error without this data to support). This data gave them the edge they needed to be confident in adjusting their standard operating procedures and margins of error for their yeast re-harvesting process.

Free eBook: Leveraging Data-Driven Fermentation Performance Management

Can fermentation management be improved, as a process? This eBook explores, in detail, how fermentation performance data analysis helps elevate product and business outcomes in a modern brewery, whether brewpub, microbrewery or regional craft brewer.

You will learn:

- Day-by-day performance considerations – learned through the extensive examination of real-time fermentation tank data.

- Key recommendations from the Precision Fermentation science team at each major step of fermentation – “Day zero” (i.e. before you pitch your yeast), the first 24 hours, and day two through the end of fermentation.

- Best practices – Activity to watch out for, broken down by each key measurement – Dissolved oxygen, gravity, pH, pressure, internal/external temperature, and conductivity.

- Key findings that can help you solve problems and improve your results.