Increase your Brewery’s Efficiency & Quality Control with Beer30™

A guest blog post, from Precision Fermentation technology partner, The 5th Ingredient®.

There is something to be said for partnering with people who share your values. At The 5th Ingredient, our mantra is #BrewBetterBeer, and we accomplish that by providing professional brewers with an all-in-one dashboard that makes it easier, not only to brew better beer, but increase efficiencies, monitor goods and expenses, and maximize profitability.

So, it wasn’t long after meeting Precision Fermentation’s team that we saw how much we have in common. Both of our businesses contribute to the ultimate mission of upping breweries’ games so they can overcome obstacles in a faster, nimbler manner than ever before. As such, we’ve partnered to expertly integrate our products and services to be even more beneficial for our brewing industry clients.

The fact that you are here, visiting Precision Fermentation’s website and perusing their (rather impressive) blog means you share common ground with us, as well. You understand that modern innovations and technologies can play an invaluable role in improving countless aspects of brewery life. We don’t have to sell you on that, and that’s good, because selling isn’t why we’re here. We get that you get it, we appreciate that, and we’re excited to show you how our Beer30 software meshes seamlessly with Precision Fermentation’s BrewMonitor System to make it an even more powerful and dynamic tool.

Improving Quality Control in your Brewery with Beer30 + BrewMonitor’s Integration

Practicing quality control can be a challenge at almost any brewery. Breweries typically run lean; it’s the nature of the beast. So, when it comes to QC, a head brewer is often strapped for time, folding this important responsibility into their already lengthy list of duties, or quality assurance is delegated to another member of the brewing team. Either scenario usually involves the default QC tech conducting rushed spot-checks between hop-additions, during lautering and transfers or in the midst of numerous brew-day activities, which is hardly ideal.

Here-and-there tests and analyses conducted as time allows are no substitute for BrewMonitor’s always-on, automated, from-the-fermenter results. If you have added BrewMonitor’s analytical suite to your arsenal, you’ve made a significant step toward QC improvement and are better able to defend against fermentation catastrophes, lost beer, recalls and resultant expenses. Given the quality of Precision Fermentation’s system, you may think life can’t get much better, but with Beer30 it really, really can.

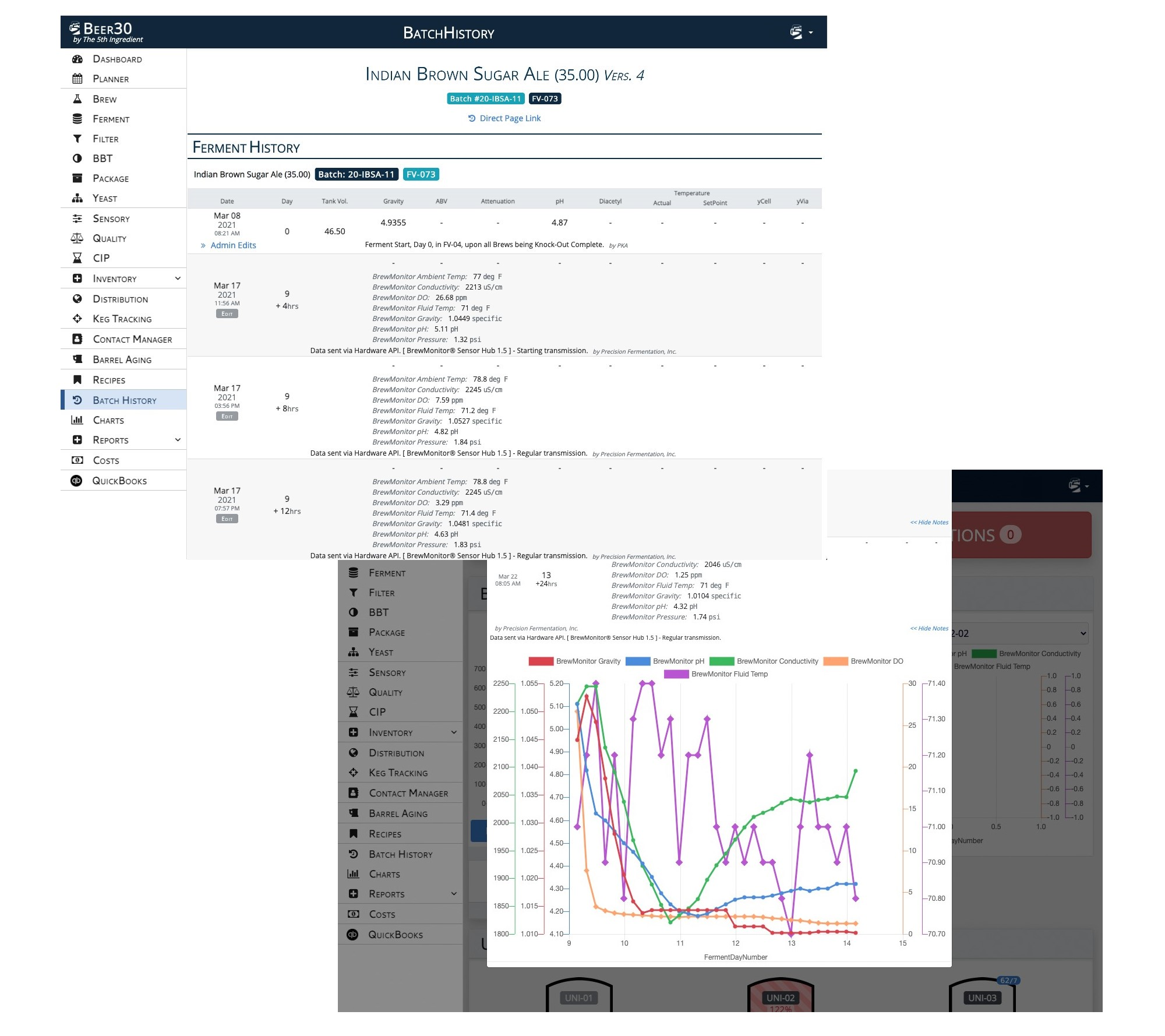

We take the incredibly useful, real-time data streamed by BrewMonitor and present it in a batch-by-batch fashion that allows you to easily monitor the contents of each vessel in your cellar, tracking data points at regular intervals. That info is stored over time, making it easy to review vital data for your brewery and the beers produced in it with ease. So, whether you’re conducting an at-a-glance check-in or a historic deep-dive of every batch over the life of a flagship beer, you’ll have everything you need at your fingertips, presented in an easy-to-digest fashion at the click of a mouse.

BrewMonitor data being sent directly into Beer30 by The 5th Ingredient.

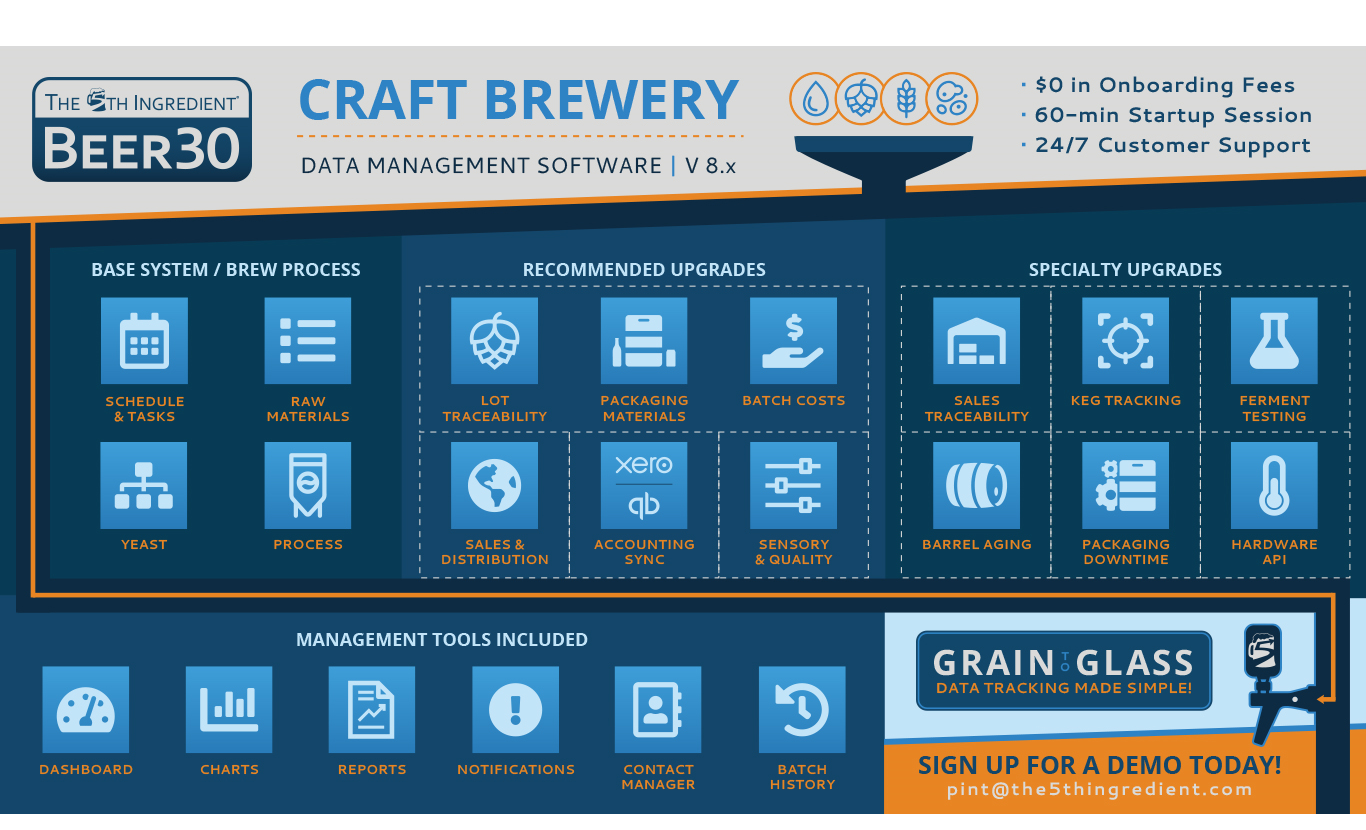

Beer30 is built with the brewer in mind, for grain-to-glass tracking

Our software isn’t a one-off version of a product developed for another industry. Brewing industry veterans with real-life experience designed Beer30 with brewers in mind. You are our audience and the only end users we had in mind from the start.

We understand the flow and mechanics of commercial breweries—from neighborhood nanos to brewpub chains to large, internationally distributed packaging operations—and cover every operational aspect from brewing, fermentation, and yeast management, to packaging, inventory, and cost-of-goods analysis, plus everything in between, eliminating the need for complicated, custom spreadsheets, sloppy whiteboard charts and diagrams, and other makeshift, far less effective organizational contrivances. Doing so will save your company time and money from day one.

With Beer30, there’s no more fitting in QC tests, traversing the brewery floor to check out on-paper tank sheets, lengthy mathematical exercises and calculations for costs, constant inventorying, retrieval of scattered information for reports or getting to the bottom of operational problems. Everything you need is in one place, entirely mobile and tablet friendly, logically organized and ready to serve your brewery and help brewers, managers and operations personnel make intelligent decisions that help reduce costs and increase profitability. This is true whether you’re producing micro one-barrel brews or a large brewery producing upwards of 120 barrels per batch. Every brewing company can stand to save time, save money and work smarter versus harder.

Sign up for a demo of Beer30 by The 5th Ingredient, and see how this software can help you track data from grain-to-glass.

Making the shift from being reactive being proactive

The extensive, live streamed data that BrewMonitor provides is extremely valuable, but only if it is utilized to make improvements and solve problems before they happen. Just as Precision Fermentation goes to lengths to provide the ultimate in real-time analyses, the innovators at Beer30 (and its kombucha counterpart, Bucha30) use extensive brewery experience and tech skills to provide the ultimate user interface to present everything brewers need in one place so they can make the most of them.

Imagine a scenario where you are getting real-time data from BrewMonitor into Beer30 in regular increments every four hours. (Note: BrewMonitor will actually track the data every 10 minutes, and the user can select the Beer30 data-notification interval that works best for them). By hour 28, due to the data being sent in succession, you will be able to see that the fermentation gravity is starting to stall. With this, you can then turn to Beer30’s yeast-genealogy trees to then see what the yeast health, cell count, viability and vitality were on pitch day in order to immediately understand where to harvest and repitch yeast into the stalling tank. Instead of waiting another day for the QC team to take daily gravity readings, you can now take proactive action to fix the course of fermentation at once.

It’s just one potential scenario, but imagine the savings in time, energy and money resulting from a company’s ability to quickly and efficiently mobilize to fix that problem with yeast, or any other number of mishaps that can arise in a brewery environment. Like BrewMonitor, Beer30 represents an upfront investment that will save a great deal of money over time in less (or zero) lost batches, increased efficiency, and maximized profitability.

On top of that, we are offering a limited-time discount to Precision Fermentation customers who sign up for Beer30 by the end of June 2021 with one month free of the BrewMonitor integration and an additional 15% of their first three months of the entire Beer30 software!

Let us provide a demo to show you all Beer30 can do

No software is better equipped to make use of the valuable data BrewMonitor provides. We’re proud of what we’ve built, excited to partner with Precision Fermentation, and would love to show you what Beer30 is all about, firsthand. If you are interested in us running you through a demonstration of our software, connect for a demo today here.