BrewIQ: Real-Time, Comprehensive Fermentation Monitoring

Discover New Levels of Control and Success with Data-Driven Fermentation

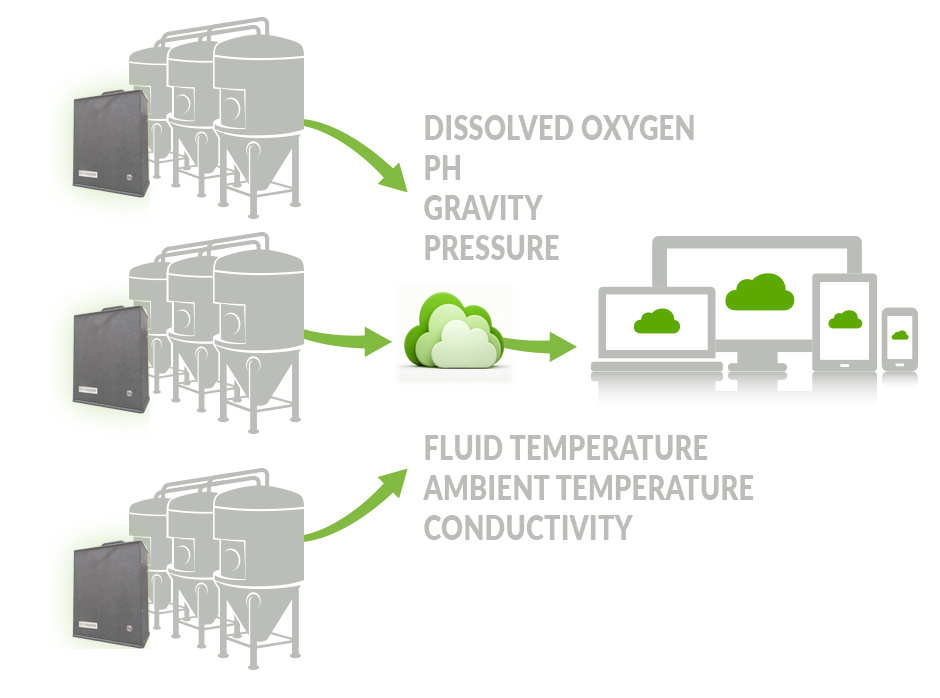

The BrewIQ System (formerly known as BrewMonitor), from Precision Fermentation, is a real-time, end-to-end fermentation monitoring and analysis solution, that is purpose-built to enable brewers to increase quality and profitability through greatly enhanced fermentation-process control. BrewIQ brings the “Internet of Things” (IoT) to the brewing process by collecting fermentation data from your existing tanks, and streaming it to your PC, tablet or smartphone, in real-time.

BrewIQ's pre-built dashboards transform your fermentation tanks into a powerhouse of insight that finally puts brewing control into your hands – ensuring brewed-product quality, increasing your production options, and saving you time and money.

The BrewIQ System: Comprehensive fermentation data streamed to any device.

BrewIQ Fermentation Hub

- Proprietary device (patent pending), connected to each existing fermentation tank

- High-density sampling

- Multi-sensor array reports real time data via cloud

- Automated cleaning

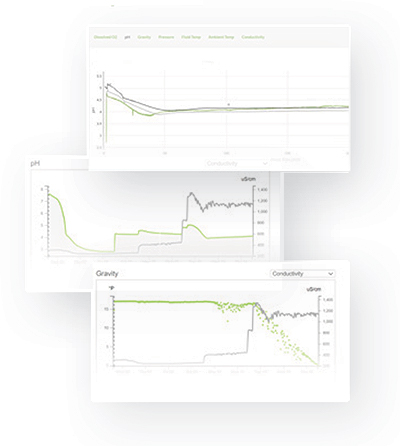

BrewIQ Dashboard

- Monitor real-time data remotely:

- Dissolved Oxygen

- pH

- Gravity

- Pressure

- Fluid Temperature

- Ambient Temperature

- Conductivity

- Access fermentation status anytime, from any web-enabled PC, tablet or phone

- Automatically triggered email and/or text alerts based on Brand and Fermentation KPIs

- Brand Analytics and Benchmarks - ensure consistency across batches

- Easily track batch-to-batch consistency with comparison and benchmarking tools

- Instantly assess yeast vitality with user-friendly comparative analytics

- Fully SaaS-based – no software to install

Data That Matters

• View all active fermentations, from multiple locations, in a single dashboard

• Get instant insight about any parameters that are out of range

• Set your own thresholds per fermentation

• Receive automatic alerts about problems, via email and text

...At Your Fingertips

• Get a graphical start-to-finish view of your fermentations from continual sampling

• Replace traditional “snapshot” view with a more complete view based on empirical data

• Use real-time data to analyze, compare and benchmark results

• Expand quality control processes to improve outcomes

Quality Control Processes, Simplified.

Get immediate, actionable information to inform your most important production decisions:

• Batch-to-Batch Quality Analysis helps easily ensure consistency and improve the quality of your operational processes.

• Yeast Vitality Trends accelerates yeast vitality assessment for more timely repitches, prevention of stalled fermentations and more, saving time and cost.

• Set custom alert thresholds, per fermentation and for each measurement, to receive the most relevant alerts about problems

• Replace traditional “snapshot” sampling with exponentially more data: ~1,000 data points per day

• Enter and save manual measurements together with automatic readings for centralized storage and full analysis of all data sources

• Expand quality control processes to improve outcomes, save time and reduce costs

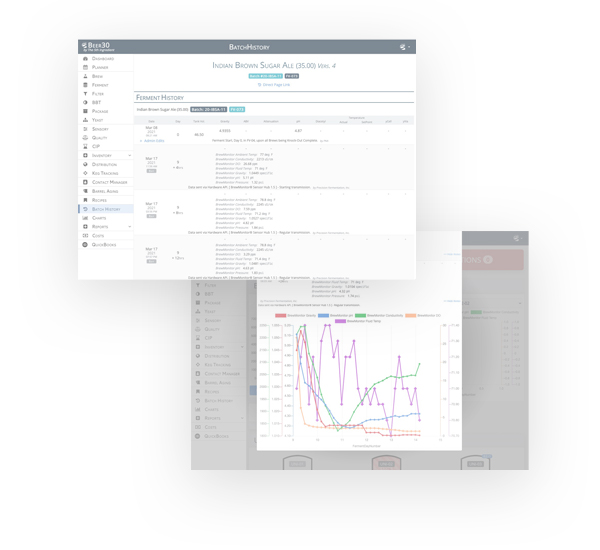

Beer30 Integration

Add BrewIQ's automatic sampling and real-time fermentation data to your management strategy. Beer30, from The 5th Ingredient, is one of the top brewery operations management solutions available, and now you can centralize all of your fermentation data in one single dashboard with the new BrewIQ integration.

• Live-streamed fermentation data is displayed directly in your Beer30 interface: Dissolved oxygen, pH, gravity, pressure, ambient/fluid temperature, and conductivity.

• Automatic sampling replaces manual entries in Beer30, reducing the overhead of manual sampling, as well as potential errors and inconsistency associated with manual data entry.

• Easy access to both production histories and fermentation outcomes in one interface powers more complete production analyses. This enables your team to correlate detailed results from all brewery processes, at a single glance and with high accuracy, and helps ensure top beer quality, consistency, and profitability.

Tech Specs

BrewIQ Fermentation Hub

Power: 90-265VAC, 0.7A, 50/60HZ

Filter: Low-profile, external filter

Dimensions: 10” wide x 13” tall x 8” deep Weight: 14 lbs.

Weight: 14 lbs.

SmartClean software-driven cleaning process: Use supplied adapter and approved chemicals

BrewIQ System

Internet connection: Broadband recommended (not required)

WiFi: Open network or password-only accessed network required

Web browser: HTML 5-compatible, JavaScript-enabled

Key Benefits

Download BrewIQ Product Sheet

Solve Brewing Problems

- Fermentation failures

- Demand outstripping production

- Quality control issues

- Ensured consistency and reproducibility

- Shrinking profits

- Lack of data

Increase:

- Consistency

- Reproducibility

- Efficiency

- Profitability

Avoid:

x Major capital investment

x Additional labor

x Equipment purchases

x Facility expansion

Customer Success Stories

Terrapin

Beer Company

Back East

Brewing

Western Red

Brewing

Cooper and Mill

Brewing